BLENDED TAILINGS AND WASTE ROCK (With a tip o’ the hat to Andy Rudy)Individually, tailings and waste rock usually have some characteristics that could be improved upon. For example, waste rock often has a high amount of void space between the rock particles, which we geotechnical engineers quantify and express as a void ratio. Aside from wasting storage volume, this pore space allows for the movement of air and water through the waste rock deposit which can lead to acid rock drainage. Tailings, on the other hand, may be liquefiable under certain conditions, such as during or shortly following strong earthquake shaking.

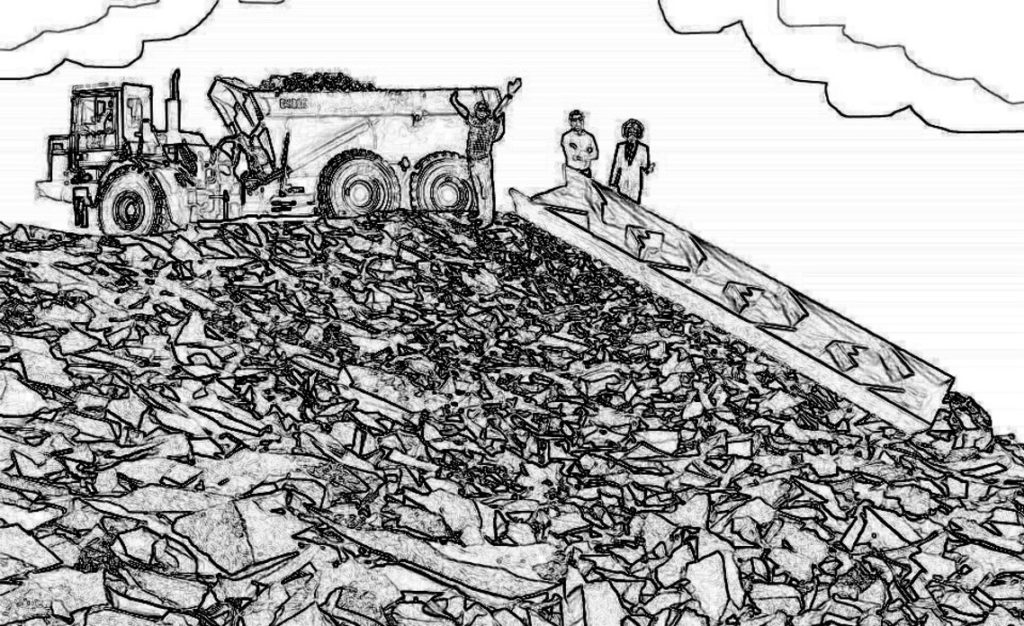

Researchers in the mining world (including this author) have been studying the characteristics and preparation methods for blending tailings and waste rock in proportions where the tailings just fill the voids in the waste rock. The resulting mix would beneficially have a low oxygen diffusion potential (and thus a low potential to generate acid rock drainage) and could potentially be non-liquefiable if the deposit is dense enough. The blended tailings and waste rock should not require a retaining embankment and could be shaped as needed to suit project requirements.

So, what’s the hold up? What are we waiting for?

Well, so far (publicly, anyway), the large-scale production of this blended material has never been demonstrated to be viable.

When I was completing active research into this application, I approached a traditional equipment supplier. They indicated to me that they could provide me with devices like a continuous concrete mixer, a flow-through ball mill or an agglomerator. Each of these devices would require crushed rock and a dilute tailings slurry. This is not a good recipe for the creation of a stable land mass. So, I partnered with Paterson & Cooke, and together we developed a static mixer. Think Pachinko machine. We demonstrated in the lab that we could successfully combine and blend dissimilar materials such as concrete sand and pea gravel, or pea gravel and tailings slurry.

Unfortunately, the project which was funding that research came to a premature end. We now have a promising technology that is seeking an application. We would like to at least bring this device into larger field-scale trials.

I know of one major mining company who has been running advanced field trials in this application, evidently using the numerous drops on conveyor belts to achieve the blending of the tailings and waste rock. We await the results of their research.

As I have often said, filtered tailings has never been, and never will be the one and only future technology for tailings.

Don’t give up on the other innovations that will be coming our way.

Comments (2)

Patrick

November 14, 2022 at 1:13 pmBryan, I am currently working on a feasibility study for a copper gold deposit that will use blended tailings and waste rock. I am the project Manager for the hydrogeology and geochemistry, as well as the QP for section 20. Last week we were asked by the client to address a comment from the regulators about the potential for contamination underneath the planned mixed waste management facility. I read both of your posts as well as your 2015 paper. I would very much like to talk to you about a test program that I need to develop.

admin

November 14, 2022 at 1:42 pmHi Patrick. Please feel free to email me at bryanulrich_pe@outlook.com so we can arrange a time to discuss.

Comments are closed.